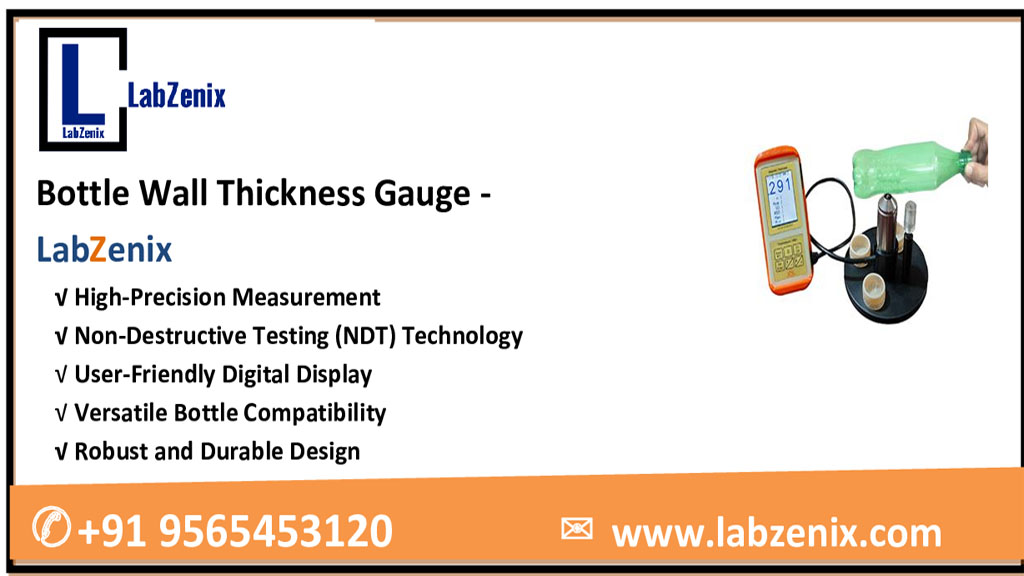

Bottle Wall Thickness Gauge – LabZenix

Bottle Wall Thickness Gauge – LabZenix

Model No: LZWTG-D

Description

Understanding the Importance of Bottle Wall Thickness Gauge – LabZenix

In the packaging enterprise, precision performs a important position in making sure product quality and durability. Bottle Wall Thickness Gauge – LabZenix is a complicated testing instrument designed to measure the thickness of bottle partitions with excessive accuracy. This device is crucial for manufacturers to hold uniformity in bottle production and make certain structural integrity.

What is a Bottle Wall Thickness Gauge?

A Wall Thickness Gauge – LabZenix is a specialised device that measures the thickness of plastic, glass, and PET bottle walls with out inflicting any harm. This non-unfavorable checking out technique lets in manufacturers to research the distribution of fabric across the bottle surface and identify inconsistencies that can impact the general electricity of the bottle.

Key Features of Bottle Wall Thickness Gauge – LabZenix

High Precision Measurement: The Wall Thickness Gauge – LabZenix affords accurate and dependable readings, making sure uniform wall thickness in bottles.

Non-Destructive Testing: It lets in producers to degree thickness with out adverse the sample.

User-Friendly Interface: The tool comes with an easy-to-use interface, making it appropriate for each experts and beginners.

Versatile Applications: It may be used to measure PET, glass, and plastic bottles in special industries.

Portable and Durable: The compact design ensures smooth portability while retaining durability for lengthy-term use.

Why is Bottle Wall Thickness Measurement Important?

Maintaining the correct wall thickness is critical in bottle manufacturing for several reasons:

1. Quality Control

The Wall Thickness Gauge – LabZenix ensures that every bottle meets the required thickness standards, preventing defects and weak spots that can lead to breakage.

2. Material Optimization

With precise thickness measurement, manufacturers can reduce material wastage by optimizing bottle design, ensuring cost-effective production without compromising quality.

3. Strength and Durability

Uniform wall thickness enhances the strength of bottles, preventing deformation and ensuring they can withstand internal pressure, transportation, and handling.

4. Compliance with Industry Standards

Many industries have strict regulations regarding packaging quality. The Wall Thickness Gauge – LabZenix helps manufacturers comply with international standards for bottle thickness, ensuring safe and reliable packaging.

Applications of Bottle Wall Thickness Gauge – LabZenix

The Wall Thickness Gauge – LabZenix is widely used in various industries where precise thickness measurement is crucial. Some key applications include:

1. Beverage Industry

Soft drinks, juices, and bottled water require strong and lightweight bottles. The Bottle Wall Thickness Gauge – LabZenix ensures uniform thickness to maintain the structural integrity of beverage bottles.

2. Pharmaceutical Industry

In pharmaceutical packaging, bottle thickness directly impacts product safety. The Wall Thickness Gauge – LabZenix helps in maintaining the right specifications for medicinal bottles.

3. Cosmetic Industry

Cosmetic bottles must be both aesthetically pleasing and durable. Accurate thickness measurement prevents defects and enhances the final product’s quality.

4. Chemical Industry

Chemical storage bottles require precise wall thickness to withstand internal pressure and prevent leakage. The Wall Thickness Gauge – LabZenix ensures safety and compliance with regulations.

How Does a Bottle Wall Thickness Gauge – LabZenix Work?

The Wall Thickness Gauge – LabZenix operates on advanced sensor technology to provide precise measurements. The basic working principle involves:

Placement of the Bottle: The sample bottle is positioned on the testing platform.

Magnetic Probe Measurement: A magnetic probe is placed inside the bottle while an external sensor measures the thickness through the walls.

Instant Readings: The device instantly displays the thickness measurement on a digital screen.

Data Analysis: The results can be recorded for further analysis, quality control, and manufacturing adjustments.

Choosing the Right Bottle Wall Thickness Gauge – LabZenix

When selecting a Bottle Wall Thickness Gauge – LabZenix, manufacturers should consider:

Measurement Range: Ensure the tool can degree the specified bottle thickness.

Accuracy: Look for excessive-precision fashions that provide consistent and dependable readings.

Portability: A compact and light-weight layout makes handling and transportation easier.

Ease of Use: A person-pleasant interface permits smooth operation even for first-time users.

Durability: The device need to be sturdy sufficient to face up to business environments.

Advantages of Using Bottle Wall Thickness Gauge – LabZenix

The Bottle Wall Thickness Gauge – LabZenix offers numerous advantages that make it an essential tool for bottle manufacturers:

Enhanced Quality Control: Ensures each bottle meets the favored thickness specs.

Material Savings: Helps in optimizing cloth utilization and lowering manufacturing prices.

Prevention of Defects: Detects variations in thickness, reducing rejection prices.

Improved Bottle Strength: Guarantees durability and resistance to out of doors strain.

Compliance with Regulations: Meets industry necessities for packaging safety and reliability.

Common Issues in Bottle Manufacturing Resolved by Bottle Wall Thickness Gauge – LabZenix

Manufacturers often face challenges in bottle production, which can be resolved using the Wall Thickness Gauge – LabZenix:

Uneven Thickness Distribution: The device helps detect and correct inconsistencies in bottle wall thickness.

Weak Spots and Breakage: Identifies weak areas in bottles that may lead to breakage under pressure.

Overuse of Material: Reduces excess material usage by ensuring precise thickness control.

Regulatory Non-Compliance: Helps manufacturers adhere to packaging regulations by maintaining standard thickness levels.

Innovations in Bottle Wall Thickness Measurement

With advancements in technology, Wall Thickness Gauge – LabZenix has incorporated modern features such as:

Connectivity: Enables real-time data transfer for quality analysis.

Automated Calibration: Ensures consistent accuracy without manual adjustments.

Display: Provides a seamless user experience with intuitive controls.

Data Logging: Stores historical data for improved tracking and analysis.

Why Choose LabZenix for Bottle Wall Thickness Gauge?

LabZenix is a trusted brand in the field of testing instruments. The Bottle Wall Thickness Gauge – LabZenix stands out due to:

Unmatched Accuracy: Ensures precise measurement for superior quality control.

Robust Design: Built for durability and long-term industrial use.

Affordable Pricing: Offers cost-effective solutions without compromising performance.

Technical Support: Provides expert assistance and maintenance services.

By investing in the Bottle Wall Thickness Gauge – LabZenix, manufacturers can enhance their bottle production process, ensuring quality, efficiency, and compliance with industry standards. This device remains a critical tool for maintaining packaging excellence across various industries.

Contact – LabZenix

Call Us

+91 9565453120

Call Sales

+91 9354572961

info@labzenix.com

Address

LabZenix Industries Pvt. Ltd. 3D/98 New Industrial Town Faridabad , Haryana - 121001